The J. & E. Stevens Company was founded in 1843 in Cromwell, Connecticut, by John and Elisha Stevens. When the

firm started in 1843, only two or three workmen were employed to make six varieties of toys.

The foundry, assembly buildings and offices were located at Nooks Hill Road, alongside the railroad

tracks that facilitated delivery of pig-iron and raw materials. They started by producing

cast iron hardware, hammers and simple iron toys. The metal fabrication line also included door buttons, stubs,

plates, as well as wardrobe, coat and hat hooks. J. & E. Stevens are believed to be one of the first manufacturers

of cast iron toys in the United States. They made a variety of toys and are most famous for their mechanical banks

and cap pistols. They also made toy irons, kettles, skillets, and stoves. In 1859, the company

produced its first fire cracker pistol and by the mid-1860's the company focused almost exclusively on the production

of toys. In 1866, Russell Frisbie, the designer of a toy steam engine, joined the company as general superintendent,

designer and inventor. Frisbie was the pattern maker, mechanic and a stockholder in the company. When production

turned solely into toy making, the company expanded rapidly. In 1869 the company produced its first cast iron

mechanical bank and it was soon nationally known for its innovative designs of mechanical banks, as well as still

banks, or the traditional "piggy" banks cast of metal in the shape of animals, buildings, or other figures, with a

slot to insert the coins. By 1870 production had increased to such an extent that nearly 1000 varieties of articles,

a large number of them toys, were made, thus insuring constant employment for from 80 to 100 men and women. The

company produced a great many other types of toys, including toy cannons, but by 1928 it devoted itself exclusively

to the production of cap pistols.

The J. & E. Stevens Company was founded in 1843 in Cromwell, Connecticut, by John and Elisha Stevens. When the

firm started in 1843, only two or three workmen were employed to make six varieties of toys.

The foundry, assembly buildings and offices were located at Nooks Hill Road, alongside the railroad

tracks that facilitated delivery of pig-iron and raw materials. They started by producing

cast iron hardware, hammers and simple iron toys. The metal fabrication line also included door buttons, stubs,

plates, as well as wardrobe, coat and hat hooks. J. & E. Stevens are believed to be one of the first manufacturers

of cast iron toys in the United States. They made a variety of toys and are most famous for their mechanical banks

and cap pistols. They also made toy irons, kettles, skillets, and stoves. In 1859, the company

produced its first fire cracker pistol and by the mid-1860's the company focused almost exclusively on the production

of toys. In 1866, Russell Frisbie, the designer of a toy steam engine, joined the company as general superintendent,

designer and inventor. Frisbie was the pattern maker, mechanic and a stockholder in the company. When production

turned solely into toy making, the company expanded rapidly. In 1869 the company produced its first cast iron

mechanical bank and it was soon nationally known for its innovative designs of mechanical banks, as well as still

banks, or the traditional "piggy" banks cast of metal in the shape of animals, buildings, or other figures, with a

slot to insert the coins. By 1870 production had increased to such an extent that nearly 1000 varieties of articles,

a large number of them toys, were made, thus insuring constant employment for from 80 to 100 men and women. The

company produced a great many other types of toys, including toy cannons, but by 1928 it devoted itself exclusively

to the production of cap pistols.

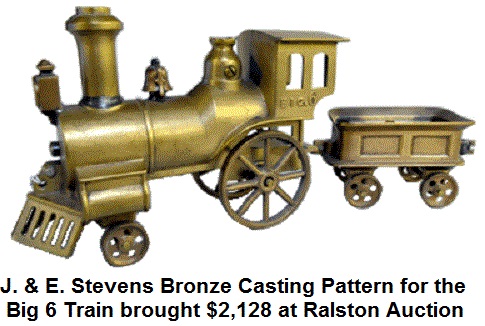

The 'BIG 6' cast iron floor train locomotive was manufactured by J. & E. Stevens of Cromwell CT in the 1880's.

It was black with red and gold trim. There were versions made with or without a bell or a headlight. The coal car

(tender) is marked 'UPRR' for the Union Pacific Railroad.

The 'BIG 6' cast iron floor train locomotive was manufactured by J. & E. Stevens of Cromwell CT in the 1880's.

It was black with red and gold trim. There were versions made with or without a bell or a headlight. The coal car

(tender) is marked 'UPRR' for the Union Pacific Railroad.

The J. & E. Stevens Company foundry room was 150 feet x 50 feet in size with windows along

the outside wall. It was located near the railroad embankment at Cromwell. In this room about 25 or 30 molders

and founders worked by the piece earning from $1.50 to $3.00 a day, according to their capacity and experience.

Their work day ended at 4:30 p.m. when all molding and pouring was finished. The craft of

iron casting consisted of three main divisions: pattern making, molding and founding. The pattern maker was

a specialized carpenter and joiner whose work was extremely important and had to be closely allied to the metal

craft. For example, one of his many considerations was the need to design the hollow wooden replica of the object

to be cast in a slightly larger size because the molten metal shrinks as it hardens. Before the pattern could be

used it was coated with varnish to provide a hard, smooth surface. This prevented the wet sand from adhering to

the pattern and protected it from damage by abrasion, moisture or warping. The molder placed the pattern in the

center of a "topless and bottomless box" into which damp sand was rammed around the mold. The top of the box,

called the cope, and the bottom, called the drag, were then carefully and tightly fitted together by means of

dowels that fitted into holes in the corners of the cope and drag. The sand used was a native product,

dampened so it would hold its shape. In the early days a simple way to judge the consistency of the sand was

to throw a handful against the building — if it stuck it was right! When the sand mold was formed a gate was

inserted in the top, as well as a vent, for the escape

of any gas during the pouring. The gate was the funnel that carried the molten iron into the mold. The completed

sand molds were then placed in rows, with aisles left between the rows for easy access by the ladlers. From one

and a half to three tons of molten iron were used each day by the founders. It was contained in the cupola

(which resembled a water tank) located high above the building. When released, the red-hot metal was drained off

through a pipe that ended in a spout in the wall of the room. Workers with long-handled, clay-lined,

iron ladles, lined up at the spout and filled their ladles. They then carried their hot burden to the rows

of sand molds and poured the melted iron into the gate. This work continued until the cupola was empty. In the

gloomy foundry, the red metal gleamed through the gate and vent holes of the molds, glowing briefly like a swarm

of large fireflies. When the castings were removed from the molds they were silvery gray in color, and were then

ready to be polished. This was done by placing them in a steam-turned tumbling barrel (a revolving cylinder)

containing fine sand or jackstones. The action of these abrasives smoothed the surface, removing any superfluous

matter from the castings. After this treatment, the articles were ready to go to the decorating and packing room

located in a long building across the street from the foundry. For finishing the toys, paint, bronze powders or

transfer engravings were quickly applied to the respective toys by 25 girls, who were seated at long benches.

They were under the supervision of Simon Wershing, an experienced painter. Using the conveniently located

railroad, the Stevens products were shipped to all parts of the United States. Customers could choose articles

from a tastefully illustrated and priced catalog which was available if a two cent stamp accompanied the request.

of any gas during the pouring. The gate was the funnel that carried the molten iron into the mold. The completed

sand molds were then placed in rows, with aisles left between the rows for easy access by the ladlers. From one

and a half to three tons of molten iron were used each day by the founders. It was contained in the cupola

(which resembled a water tank) located high above the building. When released, the red-hot metal was drained off

through a pipe that ended in a spout in the wall of the room. Workers with long-handled, clay-lined,

iron ladles, lined up at the spout and filled their ladles. They then carried their hot burden to the rows

of sand molds and poured the melted iron into the gate. This work continued until the cupola was empty. In the

gloomy foundry, the red metal gleamed through the gate and vent holes of the molds, glowing briefly like a swarm

of large fireflies. When the castings were removed from the molds they were silvery gray in color, and were then

ready to be polished. This was done by placing them in a steam-turned tumbling barrel (a revolving cylinder)

containing fine sand or jackstones. The action of these abrasives smoothed the surface, removing any superfluous

matter from the castings. After this treatment, the articles were ready to go to the decorating and packing room

located in a long building across the street from the foundry. For finishing the toys, paint, bronze powders or

transfer engravings were quickly applied to the respective toys by 25 girls, who were seated at long benches.

They were under the supervision of Simon Wershing, an experienced painter. Using the conveniently located

railroad, the Stevens products were shipped to all parts of the United States. Customers could choose articles

from a tastefully illustrated and priced catalog which was available if a two cent stamp accompanied the request.

In 1869, the J. & E. Stevens Company was incorporated, naming John Stevens as president, E.S. Coe as treasurer and

William Hulbert as secretary and superintendent. The capital stock was $140,000, with $10,000 worth of patterns and a

full assortment of manufactured goods valued at $50,000. The reorganization of the company at this time, and the omission

of his name as an officer, points to Elisha Stevens’ new venture which was the manufacture of tin toys in a partnership

with George W. Brown. In the fall of 1869, Elisha Stevens, brother of John, and George W. Brown erected a

factory close to the Connecticut Valley Railroad station at Cromwell — so close in fact, that the platform of the depot

continued into the packing room and storehouse of the factory. In this new building, which was composed mainly of windows,

nearly 300 varieties of tin and Brittania toys were produced. These toys were superior to those of cast iron, for they

were more realistic in form and lighter in weight. They could also be quickly produced by punches and drop hammers.

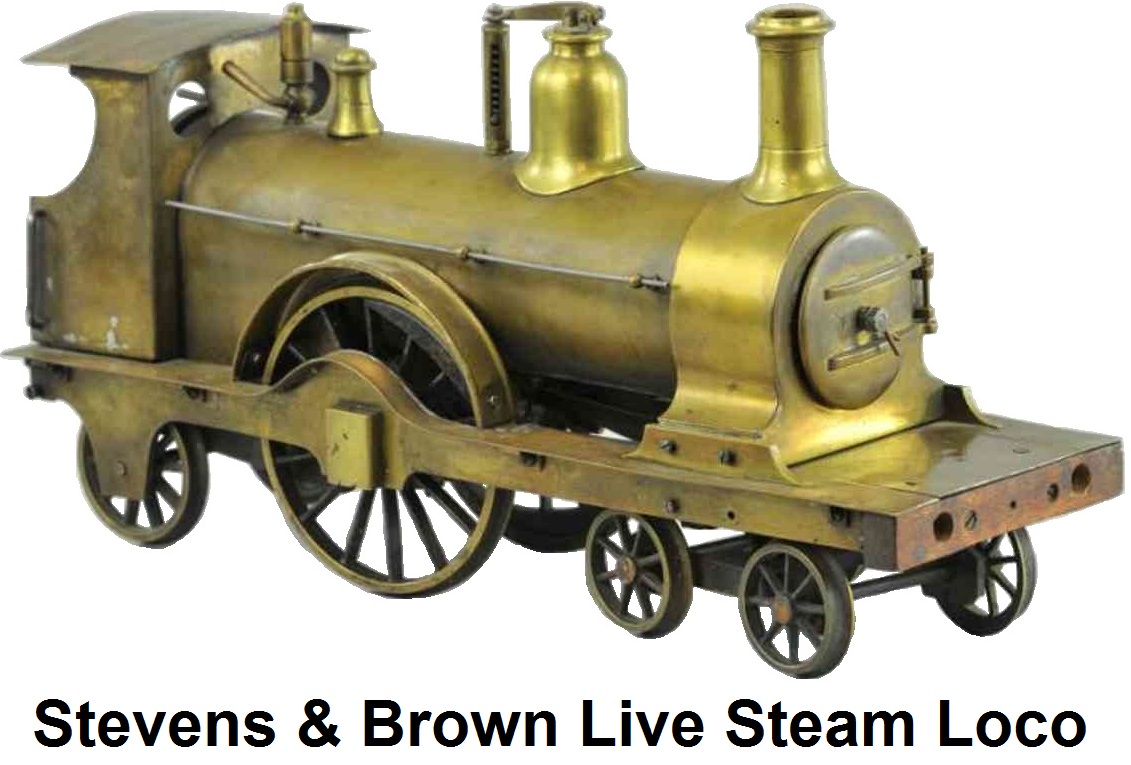

In 1871 Stevens & Brown began the production of toy steam engines that were not run by clock springs but by steam power.

Realizing that boys might want their model toy train to do more than just sit there, the Stevens & Brown Company

created the Model Dockyard Locomotive, one of the first ones that actually moved via steam propulsion. It was made of brass

and nickeled tin. The main reason why toy trains didn't move up to that point was simply that the technology didn't exist.

The model of the Dragon Dockyard Locomotive got around that limitation by using a real steam-propelled engine. This required

young kids to pour either kerosene or alcohol into the train's spirit fuel reservoir and then light it's wick to heat water

and turn it into steam. The toy steam engines of this era were nicknamed "dribblers" or "piddlers" because

they tended to leak a continuous stream of alcohol or kerosene-laden water as they rolled along the floor. This safety hazard

didn't stop the Model Dockyard Locomotive from becoming a popular children's toy back then. At this point toy trains did not

have tracks either, so kids could just set them to run on a path anywhere across the house.

In 1871 Stevens & Brown began the production of toy steam engines that were not run by clock springs but by steam power.

Realizing that boys might want their model toy train to do more than just sit there, the Stevens & Brown Company

created the Model Dockyard Locomotive, one of the first ones that actually moved via steam propulsion. It was made of brass

and nickeled tin. The main reason why toy trains didn't move up to that point was simply that the technology didn't exist.

The model of the Dragon Dockyard Locomotive got around that limitation by using a real steam-propelled engine. This required

young kids to pour either kerosene or alcohol into the train's spirit fuel reservoir and then light it's wick to heat water

and turn it into steam. The toy steam engines of this era were nicknamed "dribblers" or "piddlers" because

they tended to leak a continuous stream of alcohol or kerosene-laden water as they rolled along the floor. This safety hazard

didn't stop the Model Dockyard Locomotive from becoming a popular children's toy back then. At this point toy trains did not

have tracks either, so kids could just set them to run on a path anywhere across the house.

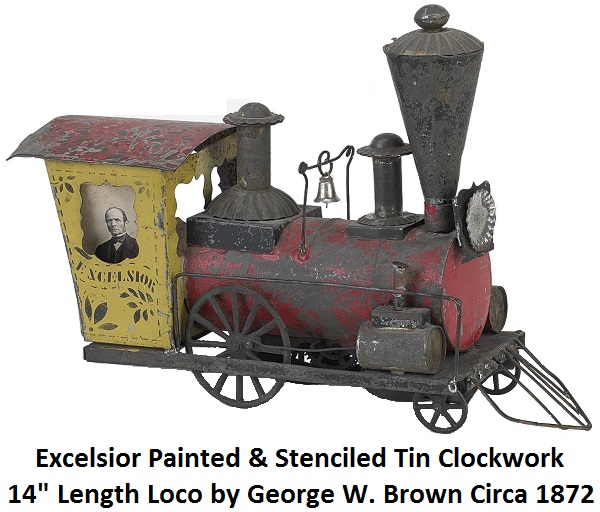

Brown, as agent for the Cromwell firm, adopted the English practice of using a pattern or sample book. This book,

contained the carefully hand-drawn and painted illustrations of the toys made by Stevens & Brown. They were identical in

size with the black and white illustrations of the company’s catalog of 1870. Manufacturing processes had evolved

considerably since the time of George W. Brown's first toy making company. To form the body of a vehicle, the heavy iron

molds of the drop hammers were raised by steam power, then quickly dropped onto a sheet of tinplate. The omnibus panels

and car bodies were stamped out in one piece, while animals were made in two halves. To make a whole animal the sides were

first cleaned with a sponge saturated with muriatic acid and then soldered together by an operator who sat at a stove on

which was a kettle of melted solder. The next step was to cool the completed animal form by dipping it in water. This whole

process was accomplished very quickly. At the Cromwell factory 20 girls were employed in the painting and packing

departments. They painted the vehicles and animals in realistic colors but stenciled the names of locomotives, boats and other

vehicles. Stencils were also used to add certain decorative details. All the finished articles were dried in two large

steam-heated chambers which were as large as a small room.

Brown, as agent for the Cromwell firm, adopted the English practice of using a pattern or sample book. This book,

contained the carefully hand-drawn and painted illustrations of the toys made by Stevens & Brown. They were identical in

size with the black and white illustrations of the company’s catalog of 1870. Manufacturing processes had evolved

considerably since the time of George W. Brown's first toy making company. To form the body of a vehicle, the heavy iron

molds of the drop hammers were raised by steam power, then quickly dropped onto a sheet of tinplate. The omnibus panels

and car bodies were stamped out in one piece, while animals were made in two halves. To make a whole animal the sides were

first cleaned with a sponge saturated with muriatic acid and then soldered together by an operator who sat at a stove on

which was a kettle of melted solder. The next step was to cool the completed animal form by dipping it in water. This whole

process was accomplished very quickly. At the Cromwell factory 20 girls were employed in the painting and packing

departments. They painted the vehicles and animals in realistic colors but stenciled the names of locomotives, boats and other

vehicles. Stencils were also used to add certain decorative details. All the finished articles were dried in two large

steam-heated chambers which were as large as a small room.

It is interesting to note that many of the non-mechanical toys illustrated in the catalog of the earlier firm of Hull and

Stafford, Clinton, Connecticut, (1850-1870) were similar to some made at Cromwell by Stevens & Brown. The date of the

end of Hull and Stafford, the similarity of its products, and the start of the Stevens and Brown factory in 1869, hints at

the possibility that Elisha Stevens absorbed the Clinton firm. The Stevens & Brown Manufacturing Company with Elisha

Stevens as its president, had a capital stock of $75,000. E.C. Phelps served as the secretary and H.F. Allison the

treasurer. George W. Brown, using his handsome pattern book, acted as the company’s agent. Their products were sold to many

firms in the United States, including The American Toy Company of New York City, and large orders for the mechanical toys

came from England.

It is interesting to note that many of the non-mechanical toys illustrated in the catalog of the earlier firm of Hull and

Stafford, Clinton, Connecticut, (1850-1870) were similar to some made at Cromwell by Stevens & Brown. The date of the

end of Hull and Stafford, the similarity of its products, and the start of the Stevens and Brown factory in 1869, hints at

the possibility that Elisha Stevens absorbed the Clinton firm. The Stevens & Brown Manufacturing Company with Elisha

Stevens as its president, had a capital stock of $75,000. E.C. Phelps served as the secretary and H.F. Allison the

treasurer. George W. Brown, using his handsome pattern book, acted as the company’s agent. Their products were sold to many

firms in the United States, including The American Toy Company of New York City, and large orders for the mechanical toys

came from England.

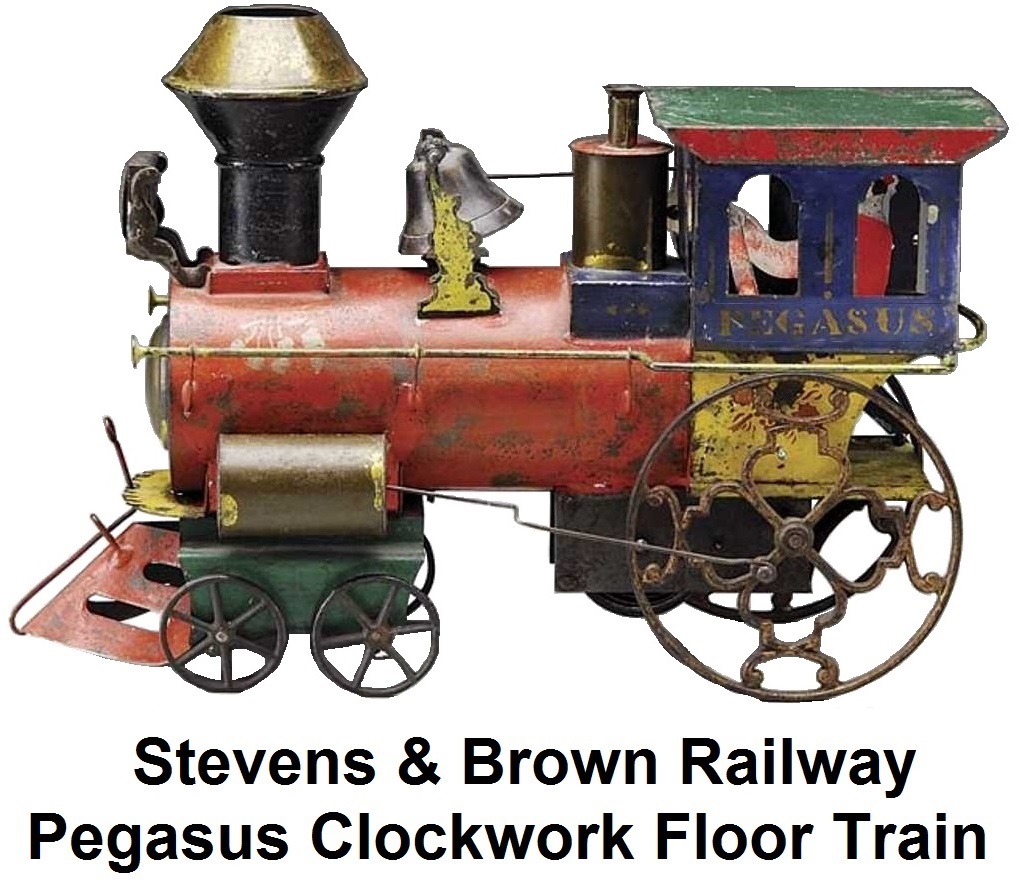

The Pegasus clockwork engine was the quintessential American tin, clockwork train engine. There are only 2 known

surviving examples in private collections today. The locomotive was a complex and desirable toy. When the clockwork

mechanism was activated the engine moved forward while the engineer, who was equipped with an articulated arm, rang

the bell. The engineer was actually constructed of three separate die cut pieces of tin, riveted together. The train

engine included such details as an articulated front pony truck, a complex front lantern, bulbous spark arrester smoke

stack, and fancifully cut-out bell support. To further add to the appeal of this toy was the finely stenciled cab area,

which included a stenciled roof, the stenciled name "Pegasus", a leaf stenciling directly under the windows and stenciled

cherries beneath the smokestack. It was painted in a multitude of vibrant colors, with a copper wash to the large ornately

cast rear wheels which were indigenous only to this toy and the large Ives Whistler. A most ingenious

locomotive patented by E.C. Phelps in 1874. One of the most complicated engines of the American tin toys. The other known

example is pictured on page 240 of American Antique Toys and the 1872 Stevens & Brown catalog. Brown patented two

intricate mechanisms in 1872 and 1874.

The Pegasus clockwork engine was the quintessential American tin, clockwork train engine. There are only 2 known

surviving examples in private collections today. The locomotive was a complex and desirable toy. When the clockwork

mechanism was activated the engine moved forward while the engineer, who was equipped with an articulated arm, rang

the bell. The engineer was actually constructed of three separate die cut pieces of tin, riveted together. The train

engine included such details as an articulated front pony truck, a complex front lantern, bulbous spark arrester smoke

stack, and fancifully cut-out bell support. To further add to the appeal of this toy was the finely stenciled cab area,

which included a stenciled roof, the stenciled name "Pegasus", a leaf stenciling directly under the windows and stenciled

cherries beneath the smokestack. It was painted in a multitude of vibrant colors, with a copper wash to the large ornately

cast rear wheels which were indigenous only to this toy and the large Ives Whistler. A most ingenious

locomotive patented by E.C. Phelps in 1874. One of the most complicated engines of the American tin toys. The other known

example is pictured on page 240 of American Antique Toys and the 1872 Stevens & Brown catalog. Brown patented two

intricate mechanisms in 1872 and 1874.

Stevens and Brown may have suffered badly during the economic depression of 1873. They also faced stiff competition from

Ives

Toys in Bridgeport. In 1880 the Stevens and Brown Company was dissolved. Elisha Stevens passed away in November of 1886

after a long illness at the age of 70. George W. Brown died of pneumonia at age 59 in New York City in 1889. The J. &

E. Stevens Company continued operations for many years. John Stevens passed away in January of 1892 of pneumonia in

Cromwell, Ct. Russell Frisbie went on to develop a gas powered automobile in 1902, and also designed three gasoline engines.

Stevens and Brown may have suffered badly during the economic depression of 1873. They also faced stiff competition from

Ives

Toys in Bridgeport. In 1880 the Stevens and Brown Company was dissolved. Elisha Stevens passed away in November of 1886

after a long illness at the age of 70. George W. Brown died of pneumonia at age 59 in New York City in 1889. The J. &

E. Stevens Company continued operations for many years. John Stevens passed away in January of 1892 of pneumonia in

Cromwell, Ct. Russell Frisbie went on to develop a gas powered automobile in 1902, and also designed three gasoline engines.

The J. & E. Stevens Company closed during World War II due to the shortage of iron, and it was sold to Buckley

Brothers in New York in 1950. The process of melting iron for the manufacture of toys and cap pistols was abandoned

shortly thereafter. Manufacturing converted to electric and gas furnaces and later to the mechanized die cast process.

The J. & E. Stevens Company closed during World War II due to the shortage of iron, and it was sold to Buckley

Brothers in New York in 1950. The process of melting iron for the manufacture of toys and cap pistols was abandoned

shortly thereafter. Manufacturing converted to electric and gas furnaces and later to the mechanized die cast process.

While many of the toys of a hundred years ago have disappeared due to the hard use given them by

children, a fair number have survived and are now cherished at museums and by private collectors. The toys created by

the George W. Brown Company, J. & E. Stevens, and Stevens & Brown are highly collectible and sought after.

In December of 1991 a hand-painted, four-wheeled fire-hose carriage, made about 1870 by George W. Brown, was bought by

an anonymous person at Christie's New York Park Avenue auction galleries, for $231,000.

A footnote to the J. & E. Stevens story: In April of 2009 the Lloyd Ralston Gallery held a toy auction of what may

have very well been the mother lode for mechanical bank and cast iron toy collectors. Roughly one-third of the remaining

unused inventory, parts, patterns and molds from the J. & E. Stevens manufacturing company crossed the auction block.

More than 80 patterns, 40 banks, 20 molds, parts, tools, jigs and

boxes were offered in the sale and all were enthusiastically received by a core group of historically minded toy collectors.

The entire collection came from a single collector who was an ex-Stevens employee. The consignor lived in a town next to

Cromwell where the Stevens factory was located and when the factory closed down the consignor’s grandfather took home

one-third of what was left behind. To the average person assessing the material in 1959, the accumulation probably had every

appearance of being worthless; however, to someone that had been working at the factory for decades, there was an

appreciation and it was apparently deemed priceless. Hand carved wooden models of tools; the actual cast-metal tools that

were used to assemble the banks on a daily basis at the factory; the bronze master bank and toy patterns; and the sand molds

themselves, these were the tools of the trade, its lifeblood, its history. Surely thanking the foresight of a historically

right-minded worker, customers flocked to Ralston’s to battle it out for the rusty accumulation. And almost as if his

grandfather had foretold in 1959, those boxes were blessed at some point during the ensuing five decades later with Midas’s

touch. The accumulation had been divided up into more than 400 lots by Ralston, with at least one selling in excess of

$20,000, and the auction posting a sales total of more than $313,000. The bronze casting for the Big 6 train set consisting

of a locomotive, tender and three gondola cars brought $2,128.

boxes were offered in the sale and all were enthusiastically received by a core group of historically minded toy collectors.

The entire collection came from a single collector who was an ex-Stevens employee. The consignor lived in a town next to

Cromwell where the Stevens factory was located and when the factory closed down the consignor’s grandfather took home

one-third of what was left behind. To the average person assessing the material in 1959, the accumulation probably had every

appearance of being worthless; however, to someone that had been working at the factory for decades, there was an

appreciation and it was apparently deemed priceless. Hand carved wooden models of tools; the actual cast-metal tools that

were used to assemble the banks on a daily basis at the factory; the bronze master bank and toy patterns; and the sand molds

themselves, these were the tools of the trade, its lifeblood, its history. Surely thanking the foresight of a historically

right-minded worker, customers flocked to Ralston’s to battle it out for the rusty accumulation. And almost as if his

grandfather had foretold in 1959, those boxes were blessed at some point during the ensuing five decades later with Midas’s

touch. The accumulation had been divided up into more than 400 lots by Ralston, with at least one selling in excess of

$20,000, and the auction posting a sales total of more than $313,000. The bronze casting for the Big 6 train set consisting

of a locomotive, tender and three gondola cars brought $2,128.